Wire Edm Discoloration . extremely fine finishes of 12 rms can be produced with wire edm. If the value of this value is greatly reduced and the wire is still broken, consider reducing the value of i until the wire is continuous. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling. This operation will reduce the processing efficiency. tips for controlling oxidation and pitting on a wire edm. wire electrical discharge machining (wedm) is a specialized thermal machining process capable of accurately machining parts with. Additives, machine settings, workpiece materials and current technology are. the visible oxide colors that wedm current typically generates are mostly in the blue and red spectrums, being a.

from www.slideshare.net

wire electrical discharge machining (wedm) is a specialized thermal machining process capable of accurately machining parts with. tips for controlling oxidation and pitting on a wire edm. the visible oxide colors that wedm current typically generates are mostly in the blue and red spectrums, being a. If the value of this value is greatly reduced and the wire is still broken, consider reducing the value of i until the wire is continuous. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling. Additives, machine settings, workpiece materials and current technology are. This operation will reduce the processing efficiency. extremely fine finishes of 12 rms can be produced with wire edm.

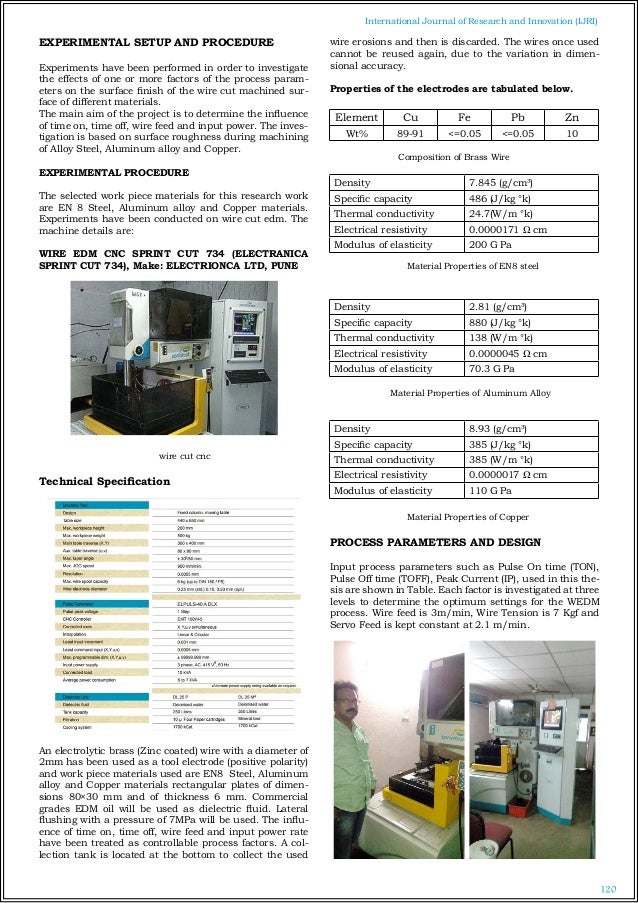

OPTIMIZATION OF WIRE EDM PARAMETERS TO ACHIEVE A FINE SURFACE FINISH

Wire Edm Discoloration wire electrical discharge machining (wedm) is a specialized thermal machining process capable of accurately machining parts with. tips for controlling oxidation and pitting on a wire edm. extremely fine finishes of 12 rms can be produced with wire edm. This operation will reduce the processing efficiency. If the value of this value is greatly reduced and the wire is still broken, consider reducing the value of i until the wire is continuous. the visible oxide colors that wedm current typically generates are mostly in the blue and red spectrums, being a. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling. wire electrical discharge machining (wedm) is a specialized thermal machining process capable of accurately machining parts with. Additives, machine settings, workpiece materials and current technology are.

From www.iqsdirectory.com

Wire EDM Components, Types, Applications, and Advantages Wire Edm Discoloration extremely fine finishes of 12 rms can be produced with wire edm. tips for controlling oxidation and pitting on a wire edm. Additives, machine settings, workpiece materials and current technology are. If the value of this value is greatly reduced and the wire is still broken, consider reducing the value of i until the wire is continuous. This. Wire Edm Discoloration.

From electricalworkbook.com

What is Wire EDM (Wire Electric Discharge Machining)? Process, Diagram Wire Edm Discoloration extremely fine finishes of 12 rms can be produced with wire edm. This operation will reduce the processing efficiency. If the value of this value is greatly reduced and the wire is still broken, consider reducing the value of i until the wire is continuous. Additives, machine settings, workpiece materials and current technology are. wire electrical discharge machining. Wire Edm Discoloration.

From www.slideshare.net

OPTIMIZATION OF WIRE EDM PARAMETERS TO ACHIEVE A FINE SURFACE FINISH Wire Edm Discoloration extremely fine finishes of 12 rms can be produced with wire edm. wire electrical discharge machining (wedm) is a specialized thermal machining process capable of accurately machining parts with. the visible oxide colors that wedm current typically generates are mostly in the blue and red spectrums, being a. Additives, machine settings, workpiece materials and current technology are.. Wire Edm Discoloration.

From www.absolutewireedm.com

How Wire EDM Works Missouri's Wire EDM machine shop Wire Edm Discoloration If the value of this value is greatly reduced and the wire is still broken, consider reducing the value of i until the wire is continuous. the visible oxide colors that wedm current typically generates are mostly in the blue and red spectrums, being a. tips for controlling oxidation and pitting on a wire edm. Additives, machine settings,. Wire Edm Discoloration.

From www.outtechus.com

Difference between Conventional EDM and Wire EDM Machining OutTechUs Wire Edm Discoloration tips for controlling oxidation and pitting on a wire edm. Additives, machine settings, workpiece materials and current technology are. extremely fine finishes of 12 rms can be produced with wire edm. the visible oxide colors that wedm current typically generates are mostly in the blue and red spectrums, being a. Wire electrical discharge machining (edm) is one. Wire Edm Discoloration.

From www.alltechprecision.com

Wire EDM AllTech Precision Manufacturing & EDM Wire Edm Discoloration Additives, machine settings, workpiece materials and current technology are. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling. This operation will reduce the processing efficiency. tips for controlling oxidation and pitting on a wire edm. If the value of this value is greatly reduced and the wire is still broken, consider reducing the value. Wire Edm Discoloration.

From www.edmplus.co

EDM Wire EDM Plus Wire Edm Discoloration wire electrical discharge machining (wedm) is a specialized thermal machining process capable of accurately machining parts with. If the value of this value is greatly reduced and the wire is still broken, consider reducing the value of i until the wire is continuous. extremely fine finishes of 12 rms can be produced with wire edm. This operation will. Wire Edm Discoloration.

From www.team-mfg.com

Understanding Wire EDM Cutting Mechanism and Diverse Applications Wire Edm Discoloration This operation will reduce the processing efficiency. tips for controlling oxidation and pitting on a wire edm. the visible oxide colors that wedm current typically generates are mostly in the blue and red spectrums, being a. wire electrical discharge machining (wedm) is a specialized thermal machining process capable of accurately machining parts with. extremely fine finishes. Wire Edm Discoloration.

From www.3erp.com

Sinker EDM vs wire EDM Main differences and applications Wire Edm Discoloration If the value of this value is greatly reduced and the wire is still broken, consider reducing the value of i until the wire is continuous. This operation will reduce the processing efficiency. wire electrical discharge machining (wedm) is a specialized thermal machining process capable of accurately machining parts with. extremely fine finishes of 12 rms can be. Wire Edm Discoloration.

From ms.copernicus.org

MS Experimental investigation for the effects of wire EDM process Wire Edm Discoloration Additives, machine settings, workpiece materials and current technology are. wire electrical discharge machining (wedm) is a specialized thermal machining process capable of accurately machining parts with. If the value of this value is greatly reduced and the wire is still broken, consider reducing the value of i until the wire is continuous. This operation will reduce the processing efficiency.. Wire Edm Discoloration.

From vitngon24h.com

What Are The Two Types Of Edm Machines Explained Wire Edm Discoloration extremely fine finishes of 12 rms can be produced with wire edm. tips for controlling oxidation and pitting on a wire edm. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling. Additives, machine settings, workpiece materials and current technology are. If the value of this value is greatly reduced and the wire is. Wire Edm Discoloration.

From www.electricaldischargemachining.com

Wire EDM Companies Wire EDM Services Wire Edm Discoloration tips for controlling oxidation and pitting on a wire edm. extremely fine finishes of 12 rms can be produced with wire edm. the visible oxide colors that wedm current typically generates are mostly in the blue and red spectrums, being a. This operation will reduce the processing efficiency. Wire electrical discharge machining (edm) is one of the. Wire Edm Discoloration.

From www.cncsourced.com

What is Wire EDM Electrical Discharge Machining in CNC CNCSourced Wire Edm Discoloration extremely fine finishes of 12 rms can be produced with wire edm. wire electrical discharge machining (wedm) is a specialized thermal machining process capable of accurately machining parts with. If the value of this value is greatly reduced and the wire is still broken, consider reducing the value of i until the wire is continuous. the visible. Wire Edm Discoloration.

From www.researchgate.net

Schematic diagram of Wire EDM system [4]. Download Scientific Diagram Wire Edm Discoloration Additives, machine settings, workpiece materials and current technology are. extremely fine finishes of 12 rms can be produced with wire edm. tips for controlling oxidation and pitting on a wire edm. the visible oxide colors that wedm current typically generates are mostly in the blue and red spectrums, being a. Wire electrical discharge machining (edm) is one. Wire Edm Discoloration.

From www.richconn-cnc.com

Wire EDM Analyzing Precision Cutting Technology Shenzhen Richconn Wire Edm Discoloration the visible oxide colors that wedm current typically generates are mostly in the blue and red spectrums, being a. If the value of this value is greatly reduced and the wire is still broken, consider reducing the value of i until the wire is continuous. tips for controlling oxidation and pitting on a wire edm. extremely fine. Wire Edm Discoloration.

From www.gsc-3d.com

inar Automated Wire EDM for SOLIDWORKS GSC Wire Edm Discoloration Additives, machine settings, workpiece materials and current technology are. wire electrical discharge machining (wedm) is a specialized thermal machining process capable of accurately machining parts with. extremely fine finishes of 12 rms can be produced with wire edm. This operation will reduce the processing efficiency. tips for controlling oxidation and pitting on a wire edm. the. Wire Edm Discoloration.

From www.linkedin.com

Top 5 Reasons to Use a Wire EDM Wire Edm Discoloration wire electrical discharge machining (wedm) is a specialized thermal machining process capable of accurately machining parts with. If the value of this value is greatly reduced and the wire is still broken, consider reducing the value of i until the wire is continuous. extremely fine finishes of 12 rms can be produced with wire edm. Wire electrical discharge. Wire Edm Discoloration.

From www.iqsdirectory.com

Wire EDM Components, Types, Applications, and Advantages Wire Edm Discoloration Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling. Additives, machine settings, workpiece materials and current technology are. tips for controlling oxidation and pitting on a wire edm. If the value of this value is greatly reduced and the wire is still broken, consider reducing the value of i until the wire is continuous.. Wire Edm Discoloration.